PET films are used in magnetic recording, photographic materials, electronics, electrical insulation, industrial films, packaging decoration, screen protection, optical grade mirror surface protection and other fields. Specifically in PET film functionality, according to the functional distinction: PET film types are: PET film (original film) and PET film after secondary processing of functional films such as (PET release film, PET high-gloss bright film, PET transfer film, PET reflective film, PET anti-static film, PET heat sealing film, PET heat shrink film) and so on! For example, electrostatic film, its is by adding special antistatic agent to KL-2610 silicone glue coated in PET film to attach a conductive layer on the film surface and form a continuous phase to improve the surface conductivity so that the generated charge can leak as soon as possible.

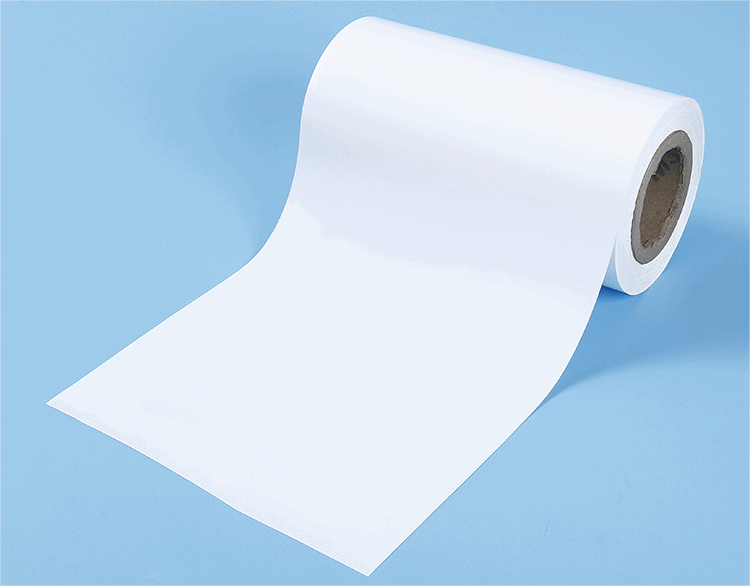

White PET film (PET white film) is obtained by adding titanium dioxide and other auxiliary materials in the production process of PET film to obtain a white surface film, which is suitable for white and smooth applications with high shading requirements, 100% pure white, low light transmission (0~30%), high coverage (70~100%), high wetting tension on the surface of the product, easy processing, surface printing Good performance, high temperature resistance, is a preferred insulating material.

Titanium dioxide is an excellent white pigment, a safe and non-toxic white powder, with excellent covering power, coloring power, good weather resistance, water resistance, not easy to turn yellow, excellent whiteness, brightness, gloss, its chemical properties are stable, generally at room temperature does not react with any substances, its main component is Tio2. main application areas in coatings, plastics, ink, paper.

By controlling the addition and adjustment of titanium dioxide, thus obtaining more than ten different whiteness, there are matte white, pearl white, bright white, porcelain white, milky white, AB black and white film, AB gray white film, etc..

Among them, the PET white film with 188u/250μm specification is usually used in solar energy backsheet, while its superior printing performance is often used in advertising spray painting industry, and the latest decoration industry is the field of strong heating carbon crystal; some of the white films are also used in silver white aluminized base film, release film base film and insulation tape industry.

Solar backsheet material, an important component in photovoltaic installations, has strict requirements for thermal, water and vapor resistance, as well as protection and support for the cells.

At the same time, photovoltaic installations are mostly built in outdoor environments, and specifications are made for insulation, barrier and aging resistance. The outermost side should be able to resist the erosion ability of the environment, the middle layer should have good insulation performance, and the inner layer should have good bonding performance. This ensures the proper use and service life of the module. PET white film is an important component of solar backsheet due to its characteristics.

Porcelain white film is usually used in label, hangtag, business card, whiteboard and advertising decoration industry, while it can be used for fashionable decorative magnets when laminated with magnetic materials; while matte white film is an aluminized base film in addition to labels.