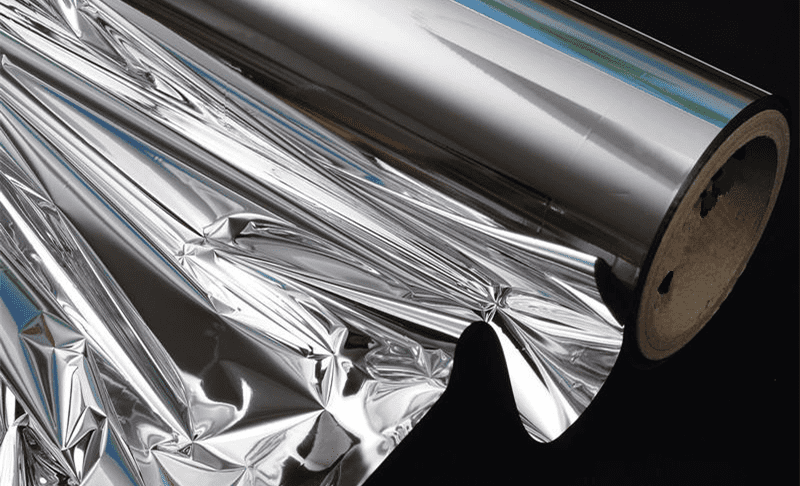

PE coated Metallized film

Metallized film is a composite flexible packaging material formed by coating a very thin layer of metal aluminum on the surface of a plastic film by a special process.

Metallized film is a composite flexible packaging material formed by coating a very thin layer of metal aluminum on the surface of a plastic film by a special process.

As one of the ten most promising technologies in the 21st century, RFID technology will win great market opportunities for the electronic information industry and its suppliers.

In the actual production process of dry lamination, there are often failures due to mechanical reasons or other factors, such as: the generation of air bubbles, …

Aluminum foil Mylar tape (Aluminum polyester tape), is made of aluminum foil and polyester film as raw materials, and is made of composite aging, winding, and slitting with glue.

Aluminized film is to evaporate high-purity aluminum wire into gaseous state at high temperature (1100~1200 ℃) through vacuum aluminizing process, and then when the plastic film passes through the vacuum evaporation chamber, the gaseous aluminum molecules are deposited on the surface of the plastic film to form a bright light.

Metallised PET film, in the production process, the transfer of the aluminized layer often occurs, which leads to the reduction of the interlayer peel strength of the composite film, the performance of the product, and even the quality of the package contents.

Have you noticed that many large public spaces such as shopping malls, stations, and hospitals do not have windows, and there are many people inside, but they do not feel that the air is too stuffy, because they all have ventilation system.

Global aluminium prices have continued to rise throughout the year due to strong demand and supply concerns, especially as aluminium production has been affected by the power crisis in China, India and elsewhere this year, with an average annual price will increase of 6% in 2022 expected , but aluminium prices will ease in the future as energy constraints dissipate.

Aluminum foil in aluminum foil laminates is not only soft in texture, good in ductility, easy to process, but also lightweight and beautiful, easy to recycle, beneficial to environmental protection, and is one of the more commonly used materials in modern packaging.

1. Aluminum polyester films

(1) Typical structure: PET/DL/AL/DL/PE or PET/AD/PE/AL/DL/PE

(Note: DL is the abbreviation of Yu-type compound,AD is rubber drilling agent).

(2) Production process: dry compound method or dry compound method after extrusion.

(3) Product features: good printing adaptability, which is conducive to improving the grade of the product; good gas and moisture barrier properties.

We will contact you within 1 working day, please pay attention to the email with the suffix “@alpetfilm.com”.