There are three main types of ducts used in household ventilation systems: rigid, semi-rigid, and flexible.

What is flexible duct?

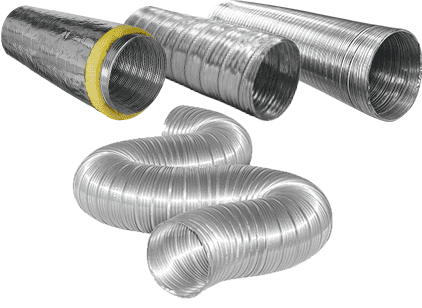

Flexible ducts are available in the following materials: PVC, PVC-coated aluminum, aluminum, and insulated aluminum. Flexible ducting is ideal when rigid ducting cannot be installed due to insufficient space or inconvenient installation.

The maximum length of flexible ducting for axial fans should not exceed 1.5 m, and that for centrifugal fans should not exceed 6 m (up to 30 L/s) and 3 m (from 31 L/s to 60 L/s). Flexible ducting systems can have up to 2 bends depending on the flow rate.

Any flexible ducting system should be pulled to ensure a full bore and to minimize drag. The best practice length to which a pipeline needs to be extended is 90% of its maximum length.

When ducting passes through unheated areas such as attic Spaces, it should be insulated with a material equivalent to at least 25 mm with a thermal conductivity of 0.04 W (mK) or less to minimize condensation.

PVC ducting is the least expensive type, but is versatile and can be used in most general ventilation connection applications, including range hoods.

What is a rigid duct?

Rigid ducting is available in plastic and expanded polypropylene (EPP) as part of larger ducting systems or as a single component of ducting. Rigid ducting should be used in the ventilation system as far as possible to minimize pipe resistance and bending in the system.

In general, rigid plastic ducting is suitable for most installations. However, EPP rigid ducting should be used when the equipment is located outside or through an unheated area such as an attic space. This type of rigid pipe provides anti-static protection and, in the case of high quality products, flame retardant to EU-82 — DIN 4102 standards.

What is a semi-rigid duct?

Semi-rigid ducting is seen as the best type of ventilation duct available and provides many benefits to installers and those who use semi-rigid ducting in their ventilation systems.

Quality semi-rigid ducting helps the ventilation system operate at optimum performance because it is a zero leakage ventilation system. In addition, it can reduce installation time by 70%. High-quality semi-rigid piping systems also have high compressive strength, with some able to withstand forces of up to 13 kN/m2.

Some semi-rigid ducting systems also allow the installer to switch between oval and circular ducting without any loss of hydraulic pressure or system performance, thus providing versatility to the installer.

The ventilation system is also easier to maintain as the leading semi-rigid ductwork offers anti-static and anti-bacterial linings that are also very easy to clean after installation.