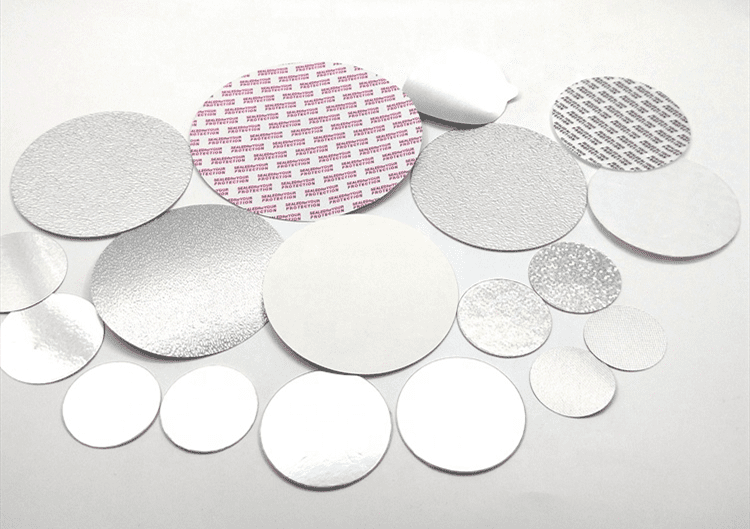

In daily life, the sealing packaging is used in many areas, such as food, cosmetics and pharmaceuticals, etc. There are various forms of sealing liners, and different package contents decide different sealing liners. To meet the needs of the market, many manufacturers are now taking use of foil heat induction seal liners. It consists of heat sealing layer, aluminum foil layer (induction layer) and backing layer. The three layers are laminated together in sequence, using electromagnetic induction to heat the aluminum foil layer, making the heat sealing layer stick to to the bottle mouth tightly, thus achieving a seal that prevents the bottle contents from being affected by the bacteria and dust in air, and avoiding leakage.

Heat sealing layer

The primary condition for the foil heat induction seal liners could seal with the bottle mouth is the sealing layer with heat sealability. The heat sealability means when the plastic is heated to molten state, it has thermal bonding properties with itself or other types of plastics. The common available films with sealability are PE (including HDPE, LLDPE, LDPE, etc.), CPP, modified PET and other polymer resins (e.g., hot-melt adhesives). Kindly note that the material used for the sealing layer is the same as the bottle material. You could refer it as below:

| The material for heat sealing layer | The material for bottle |

| PE film | LDPE, HDPE |

| CPP film | PP |

| Modified PET film | PET |

| Hot-melt adhesive | LDPE, HDPE, PP, PET, glass,ceramics. Etc. |

Mark: the hot-melt could be as the heat sealing to seal the bottle for many material. But the contents cannot be volatile and corrosive. If it is a liquid substance, it cannot be sealed in a hot filling environment.

As packaging design is demanded humanization, the material for the sealing is also improving. In recent years, heat seal material manufacturers have developed easy-peel films for different materials. So that no aluminum foil or sealing layer material remains at the mouth of the bottle after the foil seal liner is torn off. For example, CPP (PE) easy-peel heat seal film, PET easy-peel heat seal film and other high molecular material heat sealing films. Usually, these easy-peel heat seal films can only be used for encapsulate non-volatile and solvent-free products.

Induction layer — Aluminum foil

During the sealing operation, the foil liners is heated, and the heat-sealing layer is sealed with bottle month. Although the induction sealer is a heating device with non-contact. The induction layer goes hot because under the alternating magnetic field of the electromagnetic induction aluminum foil sealing machine, it generates eddy current and heats up that the sealing layer heat up and seal. Therefore, the induction layer must be a conductor. Among the various metallic conductors, aluminum foil is the most ideal one. Because of its ductility, easy processing, good electrical conductivity, and low price, it has been mass-produced in both the industrial market and the commodity market.

In general, the thickness of the induction layer- alu foil is 15um or more, e.g., 15um, 17um, 20um, 25um, 30um, etc. With the thickness of the sealing layer increasing, the efficiency of the user’s sealing operation is improving, but the material cost is also high.

Backing layer

In theory, with the heat sealing layer and induction layer, the foil heat seal liner could be sealed with bottle month. Why the backing layer is necessary?

- It is used to fill the gap between the mouth of the bottle and the cap. Due to the actual error of the injection mold, after screwing the cap, there is gap between the mouth of the bottle and the cap in the some of the bottle. The much bigger bottle month, the much bigger gap. At this time, the backing material is so important to fill into the gap to reduce poor sealing.

- Increasing the stiffness of the aluminum foil. The total thickness of the heat seal layer and the aluminum foil layer after lamination is still very thin, so it is easy to curl or deform. If it is laminated with backing material, the liner will become stiff and not easy to deform.

- Improving the efficiency of foil sealing liner insertion operations. No matter the foil gasket is inserted into the lid by an automatic gasket insertion machine or by hand, the laminated foil with a strong backing is more efficient than the liner without backing.

The backing materials basically has two characteristics: 1. the material structure is loose; 2. the material will naturally straighten under certain thickness and size conditions. Materials that meet these two requirements and are suitable for foil liner backing are generally as below:

1. Paperboard, that is, produced from virgin wood pulp or fiber pulp. This material is relatively stiff, can be compressed under certain force. It absorbs water well and is mostly used in the construction of two-piece aluminum foil sealing liner.

2. Cardboard, such as white cardboard or kraft card. This material is more firm and can be compressed under certain force. But its absorbent is not as good as the original pulp paper. The smooth surface could be printed, and mostly used in the structure of one-piece foil sealing liner.

3. EPE, the foam PE material (mostly low foam PE material). This material is looser and softer than the original pulp board and is mostly used in the construction of one-piece aluminum foil sealing gaskets. It is used for one-piece aluminum foil sealing liner. But the cost is a little higher than virgin paperboard.

4. EPS, the foamed PS material, the foam ratio is generally higher than regular item. So it is more loose than EPE, and the cost is lower than EPE. However, EPS is more troublesome to process for liner with EPS backing. Some Amway health products packaging foil liner are made of this material.