When tracking topics such as the efficiency and longevity of various parts of your system, you always need to consider the types of materials used in the various parts of your home HVAC system and related components. For example, insulation is a common area where the materials used are important, and there’s another lesser-known topic to consider: the materials used for your home’s air ducts. Did you realize that modern HVAC ducts actually come in four common material types?

Sheet metal air ducts

By far the most common material for rigid air ducts in homes today is sheet metal, which usually means galvanized steel or aluminum metal. They usually come in a variety of shapes: round, rectangular, and in some cases even spiral oval. Aluminum, in particular, is sometimes referred to as corrugated metal because its corrugated design allows the material to stand up better under the movement of joints and other areas.

The following are some of the advantages of sheet metal air ducts:

- They are usually less expensive than most other types of materials used for air ducts.

- They can be easily painted to match your trim and are not affected by water as much as other duct materials.

- They are lighter than most other types of metal used for HVAC products, so they are easier to transport and install.

- sheet metal is non-porous, which means it is not susceptible to mold or other fungi that may like to take hold in some types of plumbing materials.

On the other hand, sheet metal air ducts have some disadvantages:

- They also cannot withstand water corrosion, which can lead to rusting and other problems. (This is why it’s important to have a professional install this type of material, as unskilled installers can sometimes do more harm than good.)

- They are not as flexible or bendable as other types of ducting materials.

Stainless steel duct is a more expensive material, is often installed in commercial buildings, and may require airflow flexibility. However, it is becoming a more common choice in today’s homes, and some companies even offer the option of installing it during new construction. These ducts are more flexible and often more durable than other sheet metal types – if you can afford the higher upfront cost of these ducts, they are often the best choice for new homes or duct replacement projects.

Fiberboard ducts

Next is fiberboard ducts, which are ducts made of compressed resin sheets bonded into Plexiglas fibers. These ducts have a foil face on the outside, and this face can be embossed like any other duct or painted in a variety of colors.

Fiberboard is also excellent in terms of acoustic and thermal properties and is cheaper than any other duct material on this list. It is self-insulating, which means it can be used as an insulating material and is resistant to rodents and other pests. It can also be manufactured to any size or configuration, which is a major advantage over other types of materials.

On the downside, fiberboard ducts typically have a shorter life expectancy than other types of materials, depending on where you live and what you do with the duct. Fiberboard is not usually designed for outdoor or wetland use, and its ventilation performance leaves much to be desired.

Fiberglass ducts

Next up is fiberglass ducts, which are actually sheet metal ducts that have been lined with a fiberglass liner – either inside or outside the duct. The lining isolates the duct from air loss and also helps avoid condensation problems.

Fiberglass liners also provide solid sound insulation and reduce system noise – for this reason, they are common in a variety of office and commercial buildings. However, fiberglass can deteriorate over time, releasing particles into the air and causing health problems. Today, these pipes are not commonly found in homes.

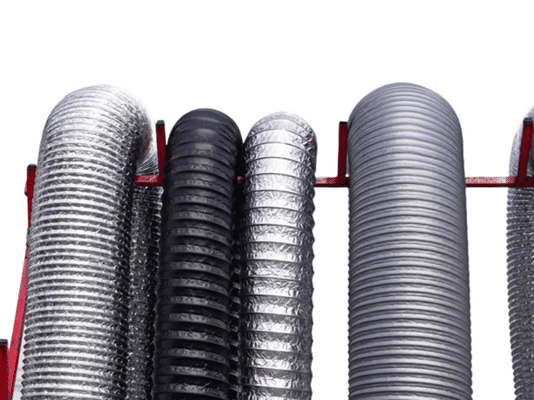

Flexible ducts

Finally, flexible ducts are ducts made of spring steel wire spirals, mounted inside 2 layers of polymer plastic. These are some of the most modern options available, with low upfront prices, light weight and very easy to install. They are extremely flexible ducts that can be applied to areas that rigid metal ducts simply cannot reach – kinks, bends and turns can all be taken into account, although these should be minimized during installation.