Fashion handicrafts and all kinds of printed clothing are more and more popular, how are these beautiful prints made? It is heat transfer technology. What is heat transfer technology? What are its features and application?

Heat transfer technology

Transfer printing refers to a printing method in which the graphics and text on the intermediate carrier film are transferred to the substrate by corresponding pressure. Screen transfer, low temperature transfer, etc. Among them, heat transfer is to use heat transfer ink (that is, thermal sublimation ink) to print any images such as portraits and landscapes on color inkjet paper (or special inkjet printing paper for thermal sublimation), or print ordinary ink on film heat. On the transfer paper, it is heated to a certain temperature within a few minutes by heat transfer heating equipment, and the pattern on the paper is vividly transferred to porcelain, glass, metal, plastic, cotton and other materials. A special printing craft.

Production process of heat transfer

The use of heat transfer technology can be widely used on objects made of porcelain, glass, metal, plastic, cotton textiles, etc. However, because heat transfer is limited by the heated area and the shape of the object, it is often necessary for objects of different areas and shapes. Use specific production tools, among which the common heat transfer production tools are mainly flat-panel machines (heat press machines), baking pan machines, baking cup machines, etc., but after all, their production methods are based on the principle of heat transfer printing. Therefore, the production steps and processes are similar, but the heat transfer tools used are different. The following are the heat transfer production steps and processes for transferring images from a flatbed machine to clothes.

Step 1: Print out the image on a color inkjet printer.

Step 2: Put the printed pattern aside first, and start the transfer after about 15-20 minutes. When transferring, when placing the printed image on the clothes, the pattern should be face down, and then adjust the time (usually 20 seconds) according to the transfer requirements of the heat transfer equipment, and close the heating plate of the equipment ( Note: Before the transfer, the pure cotton T-shirt should spray a little darkening agent on the printing part, and it must be dried before heat transfer. ).

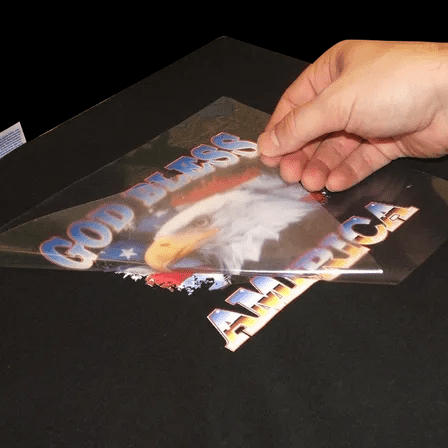

Step 3: In order to avoid the yellowing of the clothes due to the high temperature, you can put a lining cloth on the clothes before heat transfer. After the time alarm of the heat transfer equipment, lift the heating plate, quickly uncover the pattern paper, take out the clothes, and turn off the power of the equipment.

Step 4: Finally, when the temperature of the clothes cools down, fold and pack the bags, and then the entire heat transfer printing can be completed and made into a finished product.

The market demand for heat transfer printing

Compared with the current fashion and mainstream water transfer printing, what are the advantages and disadvantages of heat transfer printing technology? Specifically, the production of water transfer printing is more flexible and convenient, and is not limited by the area and shape of the object. Special tools and equipment are required (only a piece of water transfer paper is required), so its application range is wider, and the production cost is lower than that of heat transfer printing. It is very suitable for home users, small workshops, and fashion jewelry stores.

Due to the heat of the image, the color of the finished image will be firmer than that of water transfer, and it will not be easy to fade. It has corrosion resistance, impact resistance, aging resistance, wear resistance, high temperature resistance, and fire resistance. , can maintain the characteristics of ten to ten years without discoloration, so the heat transfer technology is especially suitable for drying electrical appliances, daily necessities, building materials and other objects that have special requirements for image retention.

In terms of market demand, with the continuous development of the commodity economy, various manufacturers and departments have higher and higher requirements for the trademarks, labels and packaging beauty of their own products. For the printing industry, the concept of printing has long been out of people’s impressions. Printed on traditional paper. From our daily necessities to office utensils, to products from all walks of life, such as telex, decoration, crafts, etc., more, better and more practical external packaging is required, and most of these packaging are realized by transfer printing. , so the transfer industry has a very broad and deep market space.