Common high-barrier composite films are actually made of a variety of different high-barrier materials to achieve the specified barrier effect after compounding. What are the advantages and disadvantages of these high barrier materials?

PET (polyester film)

PET film is widely used because PET’s chemical molecular structure is symmetrical and stable, the molecular chain planarity is also very good molecular chain stacking tight, easy crystallization orientation, these characteristics make PET film not only has the flatness is a good choice of barrier materials, PET film on water resistance, usually used in the pharmaceutical composite film in the surface layer (printing layer).

PA (Polyamide)

PA (nylon) is a significant advantage and disadvantage of the material, PA gas barrier performance is good, and the material is strong, ductile, good resistance to temperature, but the water vapor barrier performance is poor, water absorption, so PA even though it is a high barrier material but rarely used as a surface layer or alone, generally used in combination with other high barrier materials.

PVDC (polyvinyl chloride)

PVDC is a high-density material, oxygen and water vapor have a good barrier effect, so it is some for oxygen and water permeability requirements are very high material will be more advantageous, in the food and pharmaceutical packaging field is used more.

EVOH (ethylene drunken copolymer)

GVOH is also a good high barrier material because the molecular chain of EVOH contains hydroxyl groups, and the hydroxyl groups on the molecular chain are easy to generate hydrogen bonds between them, so that the intermolecular force is strengthened and the molecular chain is stacked more closely, which makes EVOH more crystalline and thus has excellent barrier performance. However, EVOH is also an easily hygroscopic material, and the transmission of water vapor leads to a significant reduction in barrier performance.

| Barrier materials | Advantage | Disadvantage |

| PET | Rigid material, good flatness, water and gas barrier | – |

| PA | Good flexibility, good air resistance | Poor water resistance |

| PVDC | Good air and moisture barrier performance | Contains elemental chlorine |

| EVOH | Good air and moisture barrier performance | Poor moisture absorption and heat sealability |

Each high-barrier materials have corresponding advantages and disadvantages, generally do not appear in the form of a single layer, in order to achieve a better barrier effect, soft package manufacturers will use different production processes, customized for different uses of composite packaging film.

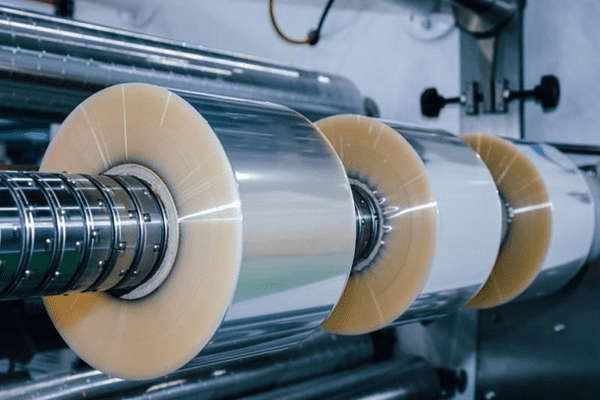

1. Compounding process: three or four layers of different materials are bonded by dry lamination or solvent-free lamination, the advantages and disadvantages between multiple layers of materials complement each other, and different factors such as water vapor, gas, fragrance and light are effectively blocked.

2. Coating process: surface coating that is the use of physical weather deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), molecular layer deposition (MLD), layer-by-layer self-assembly (LBL) or magnetron sputtering deposition and other technologies to deposit materials such as metal oxides or nitrides on the surface of the polymer, thereby forming a dense and excellent barrier performance coating on the surface of the film.

3. Nanocomposites: Nanocomposites are nanocomposites prepared by intercalation compounding, in situ polymerization or sol-gel method using impermeable sheet nanoparticles with large aspect ratio. The addition of sheet nanoparticles which can not only reduce the volume fraction of polymer matrix in the system to reduce the solubility of permeable molecules, but also can extend the permeation path of permeable molecules, reduce the diffusion rate of permeable molecules, so that the barrier performance is improved.

4. Surface modification: polymer surface due to frequent contact with the external environment, it is easy to polymer surface adsorption, barrier properties, printing impact. In order to make the polymer can be better used in daily life, the surface of the polymer is usually treated. These include: surface chemical treatment, surface graft modification, and plasma surface treatment.

Bi-directional stretching: Bi-directional stretching allows the polymer film to be oriented in both longitudinal and transverse directions, resulting in a more ordered arrangement of molecular chains and tighter stacking, which makes it more difficult for small molecules to pass through, thus improving the barrier properties, which complicates the preparation of intrinsically high barrier polymer films and makes it difficult to significantly improve the barrier properties.