Building insulation is a construction material that forms the thermal envelope of a building or otherwise reduces heat transfer.

Insulation can be based on its composition (natural or synthetic materials), form (wadding, blankets, loose fill, spray foam and panels), structural contribution (insulated concrete forms, structured panels and straw bales), functional mode (conductive, radiant, convective), resistance to heat transfer, environmental impact, etc. Heat reflective surfaces sometimes called radiant barriers are added to the material to reduce heat transfer through radiation and conduction. The choice of which material or combination of materials to use depends on a variety of factors. Some insulation materials carry health risks and some very important materials are no longer permitted but are still used in some older buildings, such as asbestos fibres and urea.

Factors affecting the type and amount of insulation used in a building include

- Thermal conductivity

- Moisture sensitivity

- Compressive strength

- Ease of installation

- Durability – resistance to degradation from compression, moisture, decomposition etc.

- Easy to replace at end of life

- Cost effective

- Toxicity

- Flammable

- Environmental impact and sustainability

Notes on construction and climate:

- Average climatic conditions in the geographical area where the building is located

- The temperature at which the building will be used

A combination of materials is often used to achieve the optimum solution and some products combine different types of insulation into a single form.

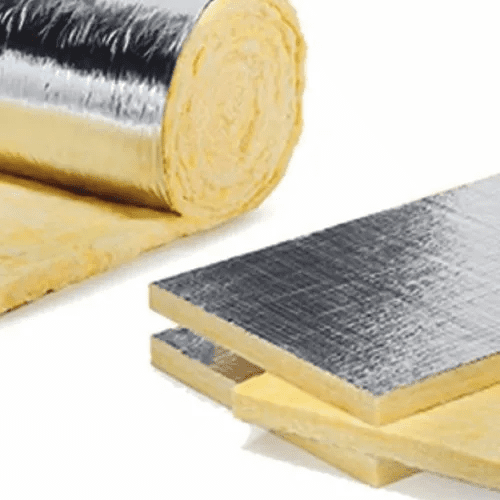

Glass fibre wadding and blankets (glass wool)

The wadding is pre-cut, while the blanket is rolled continuously. Compressing the material reduces its effectiveness. Cutting it to accommodate electrical boxes and other obstructions allows a free path for air to pass through the wall cavity. Two layers of wadding, perpendicular to each other, can be installed on unfinished attic floors to increase the effectiveness of preventing thermal bridging. The wadding can cover the joists and studs and the space between them. The wadding can be challenging and unpleasant to hang under the floor between the joists; straps or nail cloth or wire mesh on the joists can support it.

The gaps between the felt (bypasses) can become areas of air infiltration or condensation (both of which reduce the effectiveness of the insulation) and require strict attention during installation. For the same reason, careful weatherproofing and installation of a moisture barrier is required to ensure that the wool performs at its best. Air infiltration can also be reduced by adding a layer of cellulose loose fill to the top of the material.

Types

- Rock wool and slag wool. Usually made from rock (basalt, diabase) or iron ore blast furnace slag. Some rock wool contains recycled glass. Non-flammable.

- Glass fibre. Made from molten glass, usually containing 20% to 30% recycled industrial waste and post-consumer content. Non-combustible, except for the finish (if present). Sometimes manufacturers will modify the finish to make it fire resistant. Some fibreglass is unsurfaced, some is paper-faced with a thin layer of bitumen, and some is foil-faced. Paper-faced wadding is a damp-proofing agent, not a damp-proofing layer. The foil-faced wadding is the damp-proof layer. The vapour barrier must be installed on the warm side.

- High density fibreglass

- Plastic fibres, usually made from recycled plastic. Does not cause as much irritation as glass fibre, but is more difficult to cut than glass fibre. Not used in the USA. Flammable, but treated to be flame retardant.

Reflective insulation and radiation barriers

Reflective insulation and radiation barriers reduce heat radiation from the surface of the material. Radiant barriers reflect radiant energy. Radiant barriers themselves do not affect the heat conducted through the material by direct contact or the heat transferred by rising or convecting wet air. Therefore, it is difficult and inappropriate to attempt to correlate the R-value using a radiant barrier. the R-value test measures the heat transfer through the material, not to or from its surface. There is no standard test specifically designed to measure the reflection of radiant heat energy. Radiant heat is an important form of heat transfer; heat from the sun arrives through space by radiation rather than by conduction or convection. At night, the absence of heat (i.e. cold) is exactly the same phenomenon, and heat radiation is mathematically described as linearly opposite. Radiation barriers prevent radiant heat transfer in both directions equally. However, heat flow in and out of the surface also occurs through convection, which in certain geometries is different in different directions.

Reflective aluminium foil is the most common material used as a radiation barrier. It has no significant mass to absorb and retain heat. It also has a very low emissivity value of “E value” (typically 0.03 compared to 0.90 for most body insulating materials), which significantly reduces radiative heat transfer.

Types of radiation barriers

- Foil or “reflective foil laminate” (RFL).

- Foil-faced polyurethane or foil-faced polyisocyanurate panels.

- Foil-faced polystyrene. This laminated high density EPS is more flexible than rigid panels and can be used as a vapour barrier and as an insulating material. Uses include roof sheathing, ceilings and the underside of walls. For best results, it should not be used as a cavity-filling insulation.

- Foil-backed bubble wrap. This is thin, more flexible than rigid panels and acts as a moisture barrier, similar to plastic bubble wrap, with aluminium foil on both sides. Commonly used on the underside of cold pipes, cold tubes and roof sheathing.

- Light coloured roof tiles and reflective coatings. Often referred to as cool roofs, these help to keep the attic cool in the summer and in hot climates. To maximise radiant cooling at night they are often chosen for their high thermal emissivity and their low emissivity to the solar spectrum reflects heat during the day.

- Metal roofs; for example, aluminium or copper.

Radiant barriers can be used as vapour barriers and fulfil two purposes with one product.

Materials with a one-sided shine (e.g. foil-faced polystyrene) must be positioned so that the shiny side faces the air space to be effective. Foil radiant barriers can be positioned either way – the shiny side is produced by the mill during the manufacturing process and does not affect the reflection of the foil material. As the radiant barrier works by reflecting infrared energy, the aluminium foil works the same if both sides are dull.