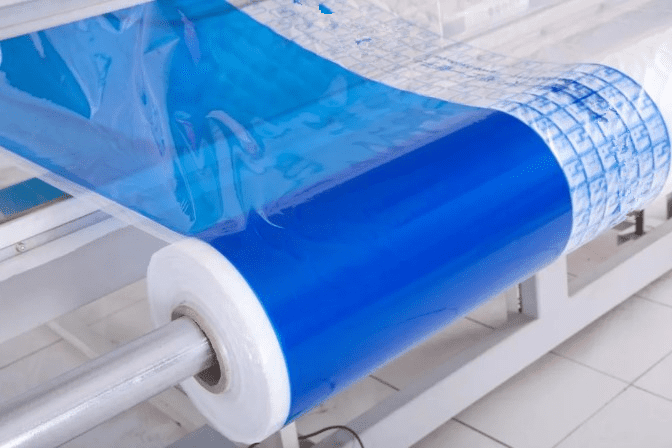

PE (Polyethylene) is a plastic product made of polyethylene resin as the base material, adding a small amount of antioxidants, slip agents and other additives. PE film is widely known for its low cost, strong functionality, good fit and tightness, and is an important substrate in the packaging industry because of its use in the consumer market. When the product needs advanced performance, PE film can be coated, laminated and metalized to create unique performance characteristics for selection in different industries.

Advantages of PE film:

1) Air permeability: It has excellent and uniform air permeability, effectively isolates moisture, and discharges heat and moisture.

2) Softness: It has an excellent hand feeling, which makes the product softer and more comfortable.

3) Mechanical properties: excellent tensile and elongation properties.

4) Chemical: Not easy to corrode, simple printing, and high temperature and light resistance.

PE/ aluminum foil lamination film

PE / aluminum foil is the most commonly used composite laminates, it usually containing pure aluminum (AL) and aluminum-plated (VMPET).

Aluminum foil is an extremely thin sheet formed by rolling high-purity aluminum several times. It is an excellent heat conductor and light-shielding body. The purity of aluminum foil for packaging is above 99.5%. Vacuum aluminized film is a kind of thin film that deposits aluminum vapor on various base films under high vacuum. The thickness of the aluminized layer is generally 350 to 400A. PE aluminum foil lamination material is a protective cover for thermal insulation materials such as foam and air bubbles. It is widely used in roof building insulation, ventilation pipes, HVAC pipes or the protective layer of foam delivery bags. It has good thermal insulation and reflection performance. PE aluminum foil lamination material increases the service life of the insulation substrate.

PE/ non-woven lamination film

PE film composite non-woven fabric is made of processed PE film and non-woven fabric, which are processed in a variety of ways in high-temperature equipment, such as film treatment, hot pressing treatment, glue spray treatment, ultrasonic treatment, etc., through composite treatment Two or three layers of fabrics can be combined together to produce products with special functions, such as high strength, high water absorption, high barrier properties, and high hydrostatic pressure resistance. PE composite materials have been widely used in medical, sanitation, protection, industry, and automotive industries.

PE /paper composite lamination film

The most common structure of PE and paper composite is kraft paper + PE + woven fabric, which is the first of metal packaging materials. The material can be moisture-proof, water-proof, oxygen-proof, rust-proof, shading, shielding, anti-static, anti-puncture, anti-backlog; suitable for all kinds of machine tools, large mechanical equipment, textile equipment, compressors, engines and other large electromechanical equipment and components export to the ocean Sexual transport packaging.

PE / nylon lamination film

Nylon is a very tough material with a density of 1.2g/cm3, good transparency, and good gloss, high tensile strength, high tensile strength, and good heat resistance, cold resistance, and oil resistance. And organic solvent resistance, good abrasion resistance, puncture resistance, and relatively soft, but the barrier to water vapor is poor, moisture absorption, moisture permeability, product packaging after nylon and PE film composite, in daily life This is the most common in PE film. This is because PE film has excellent mechanical strength and dielectric properties, and is even more resistant to moisture in humid environments. It can still maintain flexibility and chemical stability in low temperature environments. Compared with other materials, PE film has lower transparency , Flexibility is also low, and environmentally friendly and non-toxic. Mainly used in frozen packaging, general food packaging, chemical and pharmaceutical packaging, etc. Common structures are nylon + PE, PET + aluminum foil + nylon + PE, nylon + aluminum foil + PE.