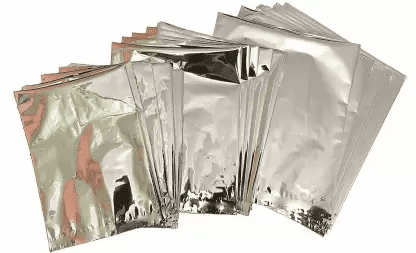

At present, people’s requirements for food packaging have been improving. And for some high temperature resistant food, the aluminum foil bag must be used. Aluminum foil food packaging has: good sealing, moisture-proof, tasteless, vacuuming effect with low permeability, and not easy to aging and other characteristics. Aluminum foil bag in the packaging of electronic components, hardware, industrial products with moisture-proof, anti-rust, anti-static, shielding, shading and other characteristics. So which field the aluminum foil packaging bags are applied? Let’s talk about it in detail.

I. Flexible foil packaging bag

Flexible packaging is a bag-type container made of soft composite packaging materials. The appearance of flexible packaging has greatly improved the mechanization and automation level of food and beverage industry, and accelerated the modernization and socialization process of people’s diet life. In developed countries, flexible packaging has become one of the main forms of food and beverage packaging, replacing cans and bottles in a certain range. In recent years, our flexible packaging market develops quickly, so far 10 aluminum foil composite production lines have been introduced, which can be used according to the different uses of flexible packaging, dry recombination, hot melting recombination, extrusion recombination and other different technologies. Flexible packaging not only has the effect of moisture-proof and fresh-keeping, but also can print various patterns and characters, which is the ideal material for modern commercial packaging. With the improvement of people’s living standards, flexible packaging aluminum foil still has a lot of space for development.

II. Aluminum foil packaging for medicine

Pharmaceutical packaging aluminum foil mainly includes easy-peeling bottle caps for water agent and injection agent and pharmaceutical PTP aluminum foil. PTP aluminum foil is widely used in the international pharmaceutical industry due to its advantages of moisture-proof, easy to carry, safety and hygiene. China began to use aluminum foil for drug packaging in 1985, and so far, aluminum foil for packaging only accounts for 20% of the drug packaging materials. In recent years, the rapid development of the drug foil market is mainly due to the rapid development of the pharmaceutical market, but mainly because of the increasing proportion of 20% aluminum foil in drug packaging.

III. The foil packaging for car

With the rapid development of Chinese automobile industry and the continuous improvement of automobile aluminization rate, the market demand for aluminum foil packaging for automobile increases rapidly. There are two kinds of aluminum foil packaging for automobile, one is the automobile air conditioner with compound aluminum foil packaging, China’s automobile air conditioner has been fully aluminized, and the annual demand for aluminum foil packaging amounts to 15,000 tons; The other is the car radiator with composite aluminum foil packaging, used for the manufacture of car water tank radiator, car condenser and evaporator, the current car water tank aluminization rate reaches 40%, the annual demand is about 0.3 million tons.

IV. Aluminum foil packaging for electrolytic capacitors.

The aluminum foil packaging used for capacitors is a corrosive material working under polar conditions, which has high requirements on the structure of aluminum foil bags. The aluminum foil bags used are divided into three kinds: cathode aluminum foil, thickness of 0.015mm ~ 0.06mm; High pressure aluminum foil, thickness of 0.065mm ~ 0.1mm, aluminum foil is required to be produced with high purity aluminum; Low pressure aluminum foil, thickness of 0.06mm ~ 0.1mm.

Domestic electrolytic capacitor aluminum foil manufacturers are few, the main market demand is not big, and the production technology and advanced countries have a big gap. But aluminum electrolytic capacitors have good performance, low price and large use, so the market prospect is very good. Japan’s annual demand is currently 45,000 tons, six times that of the Chinese market. With the development of electronic industry and China becoming a major industrial production base, the market demand for electrolytic capacitor aluminum foil packaging bag has a broad prospect.