At the weekend, after working for a week, many people always like to go to supermarket to shopping food, daily necessities or skin care products, which is prepared for the next week. When you are selecting the products on the shelf and seeing the products packaging with bad printing, folding or uneven surface, will you give up it? Believe your answer is“Sure”. Poor appearance packaging not only affects the customers’ choice, but also directly lower the sales of the product itself.

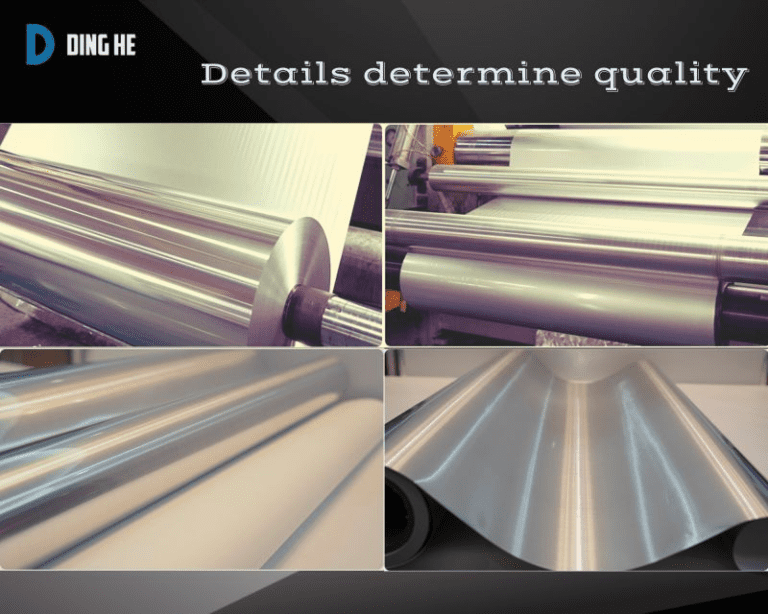

Nowadays, the flexible packaging is so popular in the packing industry on the market, due to the excellent performance, could meet the requirements of all kinds of goods. It mainly includes aluminum laminated film, plastic laminated film, metallized PET laminated film. Usually, the productivity of laminated film is very high, not just reduce the labor cost and intensity, more than lower the production cost. Therefore, no matter in the field of drug & cosmetics & food, or chemical & industry, its usage keeps increasing, what following is many quality problems:

- Nonuniform tension

If the tension of packaging film is not uniform, it shown as the inner layer of film is tight and outer layer is lax. When this film is used in automatic packing machine, it will make the machine run unstably, cause the finished bag with different size, large sealing edge deviation and so on, which is serious quality issues. So it’s necessary to check and adjust the equipment to ensure the tension uniform.

2. Unsmooth surface

As we know the packaging material surface should be smooth. When it’s uneven with 2mm concave-convex, it will be judged to be defective, and rejected by manufacturer. If the laminated film with unsmooth surface is used, the result is the same with item 1. The primary cause maybe:

A: The running of slitting machine is not stable;

B: Thickness of laminated film is uneven

C: The rolling tension is not uniform

Manufacturer could inspect and debug device according to the comment above.

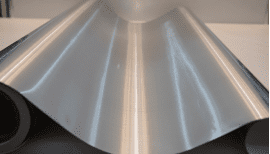

3. Wavy surface

Wavy surface means the the surface is bending and like wave. This quality defect have influence on the running status of automatic packaging device, and finally cause the problem, for example the poor sealing strength and tensile strength, deform forming bag, and asymmetric printing design. Etc. If these quality defect on the laminated film is so obvious, then it couldn’t be made bag in device.

4. Serious deviation in slitting process

In general, the slitting deviation of packaging film should be controlled within 2-3mm. If the result value exceeds it, the forming bag will be affected, like pattern is out of position and incomplete, design is not symmetry.

5. Poor joint quality

The joint quality of laminated film depends on the joint quantity, quality and marked. The joint is always flat, smooth and strong with no overlap, which located in the middle of two patterns. Beside, the adhesive tape shouldn’t be thick, otherwise, the Stuck film, broken film may arise and lead the device shutdown. In addition, there should be a distinct mark in the joint, which remind operator to examine, handle and process.

During the bag production progress, there will be various problem in the laminated film, which could be solved by adjusting the device or others. But its quality decides the usage and even packaging efficiency.