In winter, if we would like to spend a more comfortable warm winter, the heating equipment in our lives is essential. And the underfloor heating would be the ideal choice of many people. When the underfloor heating is laid, the reflective film has many roles to play in achieving increased heating effectiveness.

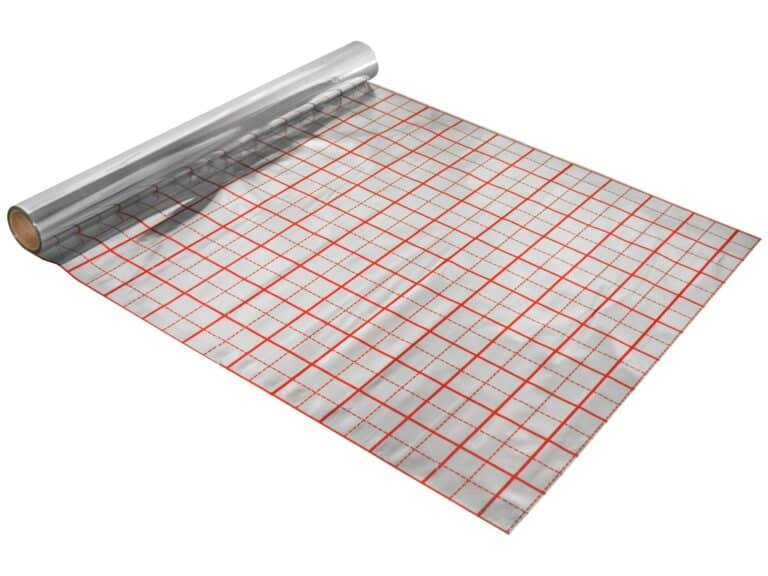

The floor reflective film is made of alu foil, PET with color design, and fiber glass by PE glue. It is a key component of the structural layer in the floor heating system which could guarantee a comfortable temperature and improves the ability to reflect and radiate heat. Therefore, the role of reflective film in floor heating is mainly to prevent heat from being dissipated from underneath, thus effectively improving heat reflection & radiation capacity, and ensuring constant indoor temperature.

Besides, there is grid on the surface of the floor heating reflective film, which is beneficial to calculate the spacing between heating pipes, that in turn facilitates the fixing of floor heating pipes and brings convenience to the construction working.

On the market, there are various types of floor heating reflective films materials. We can learn which is more suitable for your house by the following types.

1. Non-woven based reflective film

It is made by laminating alu foil with a thin non-woven fabric. Due to the poor corrosion resistance, this item has been gradually withdrawn from market.

2. Bubble MPET reflective film

Because the middle layer of bubble film is full of air, so it has the characteristics of lightness, elasticity, shockproof and anti-abrasion, etc. The insulation effect is better than other materials, but the cost is higher.

3. Foamed polyethylene MPET film

This reflective film consists of PE foam and metallized PET. Because of the thin insulation layer, the effect is poor.

4. Paper-based reflective film

Usually, the kraft paper is composited with metallized PET. Although the cost is low, the service life is short.

5. Mirror reflective film

There are two types of reflective films: metallized reflective film and aluminum PET reflective film, which is the most common reflective films on the market today. Because the reflective film has two layers of PET to protect, the corrosion resistance and reflectivity have been greatly improved.

How to select the floor relective film?

Reflectivity is one of the important indicators of floor heating reflective film. More reflective, more energy-saving. The reason why non-woven reflective film has been eliminated is only 60% reflectivity. Beside, the aluminized layer is easy to be corroded and lose reflective effect under high temperature & alkaline environment. MPET reflective film and foil PET reflective film can effectively isolate oxygen and moisture. In the alkaline environment of floor heating, it can protect the aluminum layer for a long time to prevent corrosion and prolong the service life. With a reflection rate of 99%, the energy-saving effect is remarkable. These two items currently are the mainstream products on the market.

Then, in regard to the service life, the regular non-woven MPET reflective film couldn’t isolate oxygen and moisture. With the high temperature & high-humidity atmosphere, the aluminized layer will be degraded rapidly. So that the service life won’t be over three months.Without it, the reflective film will lose the heat reflex and the energy consumption will increase by 10-20%. The floor reflective film is made of several lays PET. It lasts as long as the building even in the closed environment. Comparing with the regular non-woven reflective film, it can save 20% energy.

After learning the information above, believe people know the advantage and importance of floor reflective film, then know how to choose the suitable product for their house.